› Download SLS Factsheet (PDF)

America’s Rocket for Deep Space Exploration

NASA’s Space Launch System, or SLS, is a super heavy-lift launch vehicle that provides the foundation for human exploration beyond Earth’s orbit. With its unprecedented power and capabilities, SLS is the only rocket that can send Orion, astronauts, and cargo directly to the Moon on a single mission.

Offering more payload mass, volume capability, and energy, SLS, the world’s most powerful rocket, can carry more payload to deep space than any other vehicle. The SLS rocket is designed to be evolvable, which makes it possible to fly more types of missions, including human missions to the Moon and Mars and robotic scientific missions to places like the Moon, Mars, Saturn, and Jupiter.

The SLS team has delivered and is preparing for the Artemis I mission, NASA’s first exploration-class rocket built for human space travel since the Saturn V. Engineers and industry partners are making progress toward delivering rockets for the next several Artemis missions.

The Power to Explore Beyond Earth’s Orbit

To fulfill America’s future needs for deep space missions, SLS will evolve into increasingly more powerful configurations. SLS is designed for deep space missions and will send Orion or other cargo to the Moon, which is nearly 1,000 times farther than where NASA’s International Space Station resides in low-Earth orbit. The high-performance rocket will provide the power to help Orion reach a speed of 24,500 miles per hour—the speed needed to send it to the Moon.

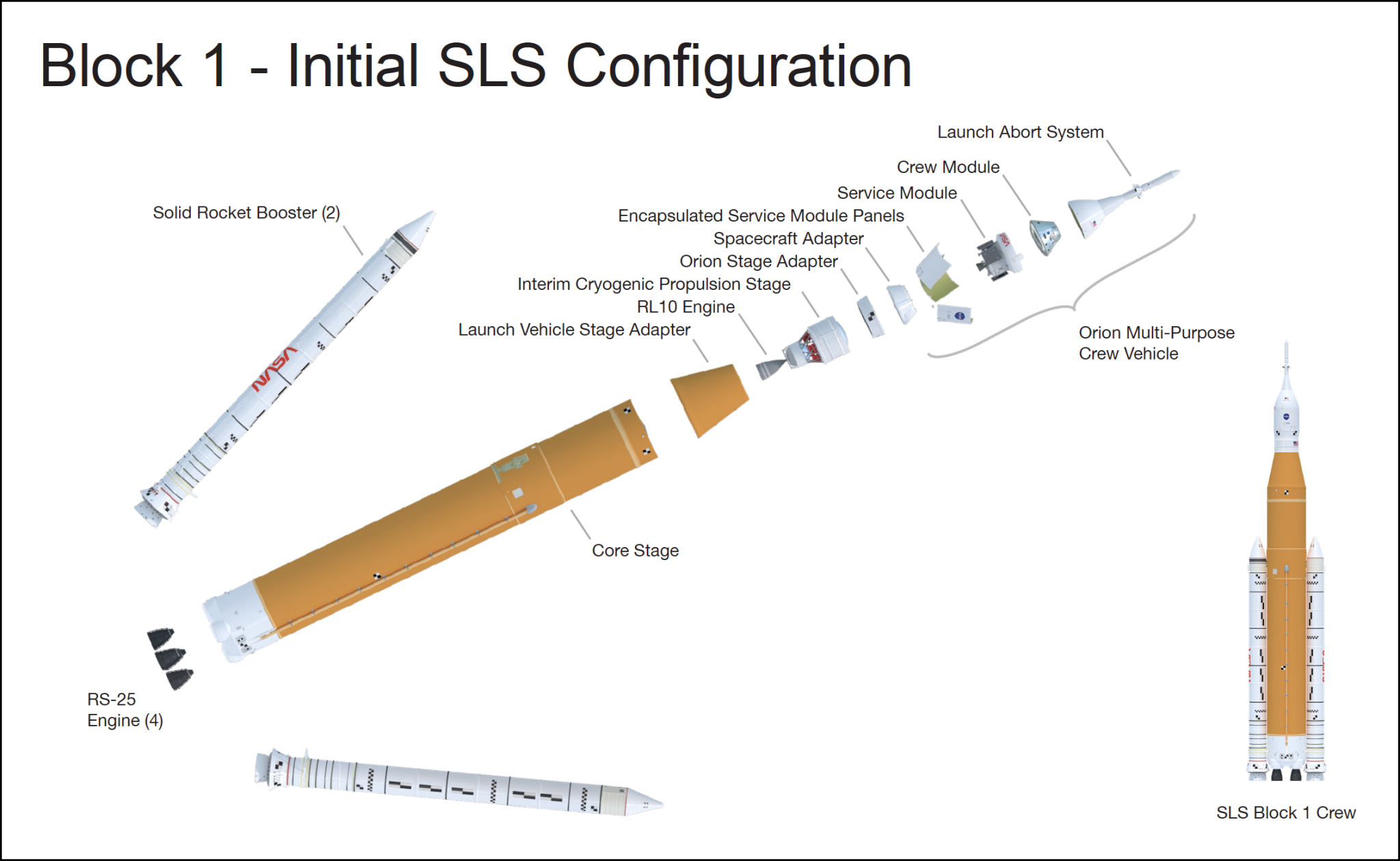

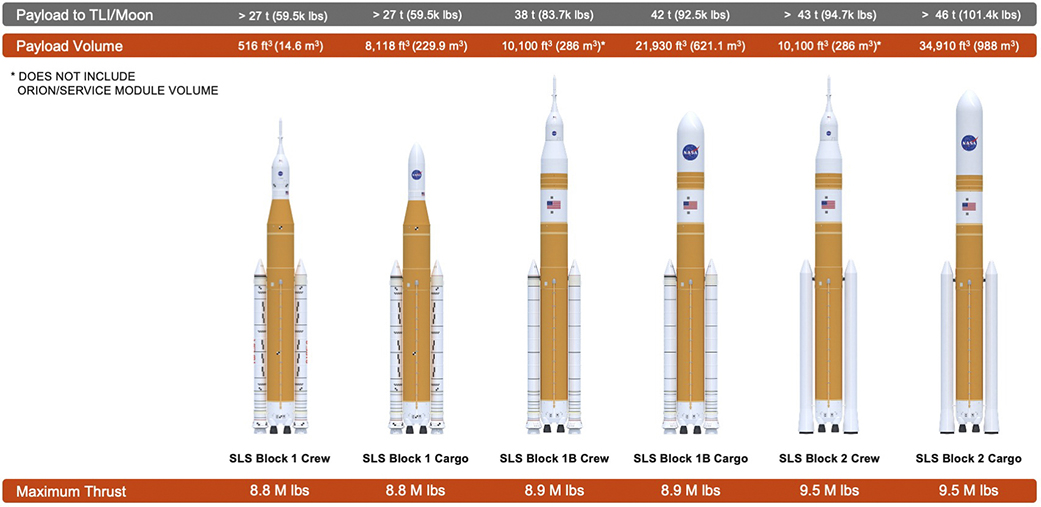

Every SLS configuration uses the core stage with four RS-25 engines. The first SLS vehicle, called Block 1, can send more than 27 metric tons (t) or 59,500 pounds (lbs.) to orbits beyond the Moon. It will be powered by twin five-segment solid rocket boosters and four RS-25 liquid propellant engines. After reaching space, the Interim Cryogenic Propulsion Stage (ICPS ) sends Orion on to the Moon. The first three Artemis missions will use a Block 1 rocket with an ICPS.

Block 1B crew vehicle will use a new, more powerful Exploration Upper Stage (EUS) to enable more ambitious missions. The Block 1B vehicle can, in a single launch, carry the Orion crew vehicle along with large cargos for exploration systems needed to support a sustained presence on the Moon.

The Block 1B crew vehicle can send 38 t (83,700 lbs.) to deep space including Orion and its crew. Launching with cargo only, SLS has a large volume payload fairing to send larger exploration systems to the Moon and Mars or for science spacecraft on solar system exploration missions.

The next SLS configuration, Block 2, will provide 9.5 million lbs. of thrust and will be the workhorse vehicle for sending cargo to the Moon, Mars, and other deep space destinations.

SLS Block 2 will be designed to lift more than 46 t (101,400 lbs.) to deep space. An evolvable design provides the nation with a rocket able to pioneer new human and robotic spaceflight missions.

Space Launch System Missions

Artemis I, the first integrated flight of SLS and Orion, uses the Block 1 configuration, which stands 322 feet, taller than the Statue of Liberty, and weighs 5.75 million lbs. During launch and ascent, SLS will produce 8.8 million lbs. of maximum thrust, 15 percent more thrust than the Saturn V rocket.

For Artemis I, Block 1 will launch an uncrewed Orion spacecraft to an orbit 40,000 miles beyond the Moon, or 280,000 miles from Earth. This mission will demonstrate the integrated system performance of SLS, Orion, and Exploration Ground Systems prior to a crewed flight. The Artemis II mission will send astronauts on a flight to orbit the Moon. These missions pave the way for landing astronauts on the Moon.

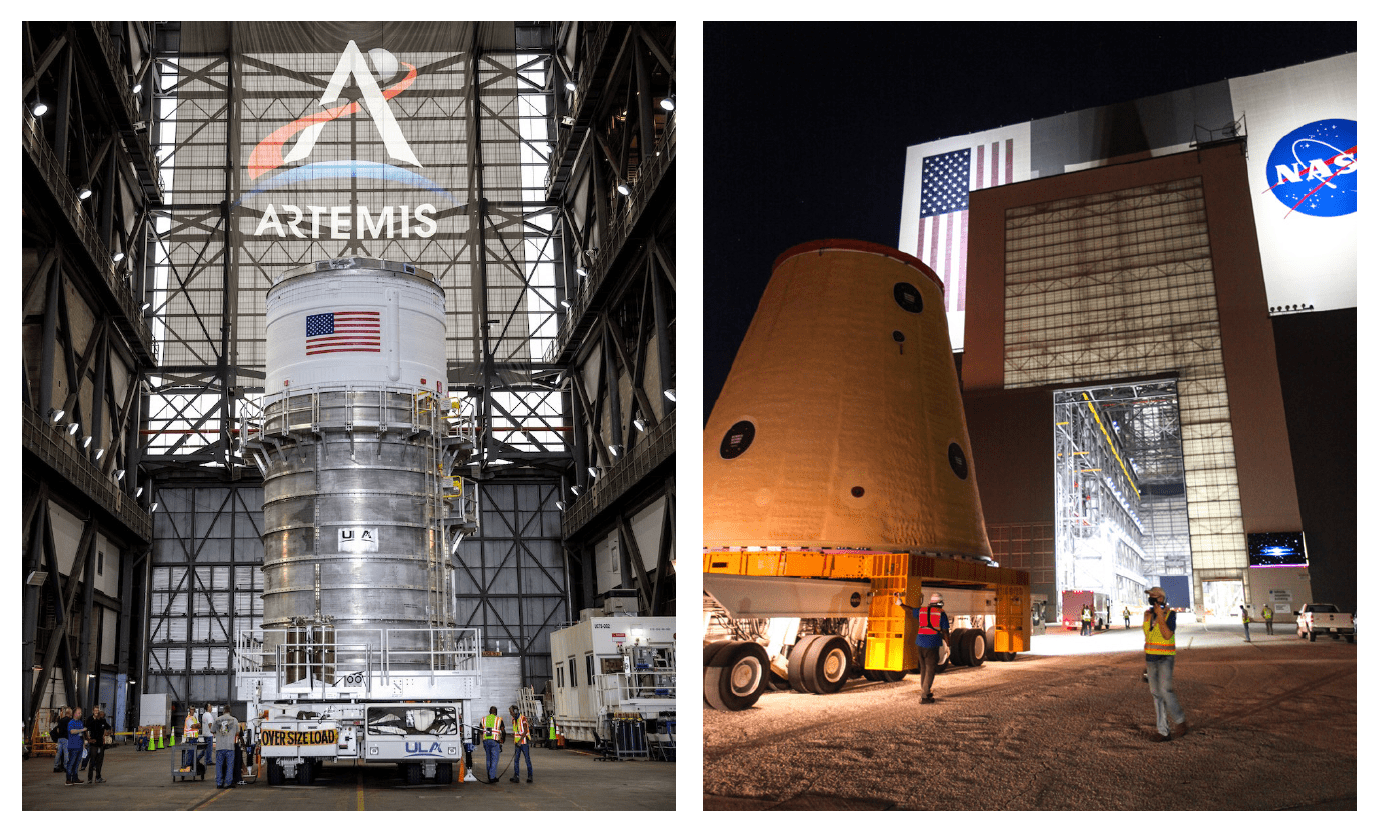

Building the Rocket

NASA is building the rockets needed for several missions. To reduce cost and development time, NASA is upgrading proven hardware from the space shuttle and other exploration programs while making use of cutting-edge tooling and manufacturing technology. Some parts of the rocket are new and other parts have been upgraded with modern features that meet the needs of deep space missions, which require higher launch vehicle performance levels.

Core Stage

The Boeing Company, in Huntsville, Alabama, builds the SLS core stages, including the avionics that controls the vehicle during flight. Towering more than 212 feet with a diameter of 27.6 feet, the core stage stores 730,000 gallons of super-cooled liquid hydrogen and liquid oxygen that fuel the RS-25 engines. Core stages are built at NASA’s Michoud Assembly Facility in New Orleans using state-of-the-art manufacturing equipment, including a friction stir welding tool that is the largest of its kind in the world. The core stage is the newest part of the rocket, and it successfully completed its one and only planned Green Run test series at NASA’s Stennis Space Center in Mississippi. With the Artemis I core stage complete, Boeing is building stages for the next few Artemis missions. The SLS avionics computer software is developed at NASA’s Marshall Space Flight Center in Huntsville.

RS-25 Engines

Propulsion for the SLS core stage will be provided by four RS-25 engines. Aerojet Rocketdyne of Sacramento, California, is upgrading an inventory of 16 RS-25 shuttle engines to SLS performance requirements, including a new engine controller, nozzle insulation, and required operation at 512,000 lbs. of thrust. During the flight, the four engines provide about 2 million lbs. of thrust. The SLS Program and its industry partners tested the four RS-25 engines and the entire core stage in a “Green Run” test campaign that culminated in a successful, full-duration, 500-second hot-firing at Stennis. Aerojet Rocketdyne has tested new controllers for the engines and has processed engines for follow-on flights after Artemis I. In addition, Aerojet Rocketdyne has restarted production of new RS-25 engines and is developing and testing new, advanced components to make the engines more affordable.

Boosters

Two shuttle-derived solid rocket boosters provide more than 75 percent of the vehicle’s thrust during the first two minutes of flight. The prime contractor for the boosters, Northrop Grumman’s Northern Utah team, has modified the original shuttle’s configuration of four propellant segments to a five-segment version. The design also includes new avionics, propellant grain design, and case insulation, and eliminates the recovery parachutes.

In addition to the boosters for Artemis I, Northrop Grumman has completed motor segments for Artemis II and is working on boosters for missions beyond Artemis II. Trains transport booster segments from Utah to NASA’s Kennedy Space Center in Florida where they are stacked with forward and aft assemblies to create the largest, most powerful boosters ever built for spaceflight. The boosters’ avionics systems are tested at Kennedy and Marshall.

Integrated Spacecraft/Payload Element

The initial capability to propel Orion out of Earth’s orbit for Block 1 will come from the ICPS, based on the Delta Cryogenic Second Stage used successfully on United Launch Alliance’s Delta IV family of rockets. It uses one RL10 engine made by Aerojet Rocketdyne.The engine is powered by liquid hydrogen and liquid oxygen and generates 24,750 lbs. of thrust. With two upper stages complete, United Launch Alliance is manufacturing the Artemis III ICPS.Teledyne Brown Engineering of Huntsville builds the launch vehicle stage adapter that partially encloses the ICPS and connects it to the core stage. The Orion stage adapter (OSA) will connect Orion to the ICPS on the SLS Block 1 vehicle. The OSA can accommodate several CubeSat payloads in 6 Unit or 12 Unit sizes, depending on mission parameters. For Artemis I, the OSA carries several 6U-sized CubeSats to deep space for various science and technology demonstration missions.

Exploration Upper Stage

The Exploration Upper Stage (EUS) is powered by four RL10C-3 engines that produce almost four times more thrust than the one RL10B-2 engine that powers the ICPS. This 97,000 lbs. of thrust will allow more than 38 t (83,700 lbs.) for Block 1B crew and more than 42 t (92,500 lbs.) for Block 1B cargo to be sent to the Moon. With the EUS, NASA can use a Block 1B crew configuration to send Orion, astronauts, and payloads to deep space or use a Block 1B cargo configuration to send large cargoes to the Moon, Mars, or more distant destinations. NASA completed the critical design review for the EUS in 2019. Boeing is building the EUS at Michoud. Aerojet Rocketdyne has completed manufacturing and testing of several engines.

The SLS Team

SLS is America’s rocket with more than 1,100 companies from across the U.S. and at every NASA center supporting the development of the world’s most powerful rocket. The SLS Program, managed by Marshall, works closely with the Orion Program, managed by NASA’s Johnson Space Center, and the Exploration Ground Systems Program, managed at Kennedy. All three programs are managed by the Exploration Systems Development Division within the Exploration Systems Development Mission Directorate at NASA Headquarters in Washington, D.C.

For more information about SLS, visit:

https://www.nasa.gov/artemis

https://www.nasa.gov/sls

https://twitter.com/NASA_SLS

http://www.facebook.com/NASASLS

http://www.instagram.com/exploreNASA